Press Release

Advancements in Topical Treatments for Nonwovens

Nonwovens producers continue to develop new products for existing applications, taking advantage of a more cost effective production scheme. One example is the replacement of rayon with polyester or polypropylene nonwoven fabrics. The performance demands of these fabrics remain the same, but the challenge is in replacing rayon with fabrics exhibiting similar hydrophilic and anti-static properties. Hydrophilic and anti-static properties can be imparted to polyester and polypropylene fabrics by way of topically applied additives that enhance or modify the fabric surface. Goulston Technologies, Inc. offers several variations of topically applied treatments that provide non-durable or semi-durable hydrophilic properties, hydrophobic properties, and antistatic properties.

Non-durable Hydrophilic Surface Modifiers

Nonwovens end-uses requiring products that exhibit hydrophilic properties and are designed for single use applications usually require a non-durable hydrophilic finish system. These finishes are designed to impart good initial hydrophilic character but are easily washed off revealing the underlying hydrophobic substrate. Characteristics of these treatments include excellent emulsion quality and stability, lower surface tension values (leading to uniform coverage on the fiber surface), and static protection. This specially formulated finish chemistry can be applied as a spin finish or a topcoat finish by spray, kiss roll, or dip bath application.

Semi-durable Hydrophilic Surface Modifiers

Newer markets require finish chemistries that provide hydrophilic properties thru multiple insults, or are not easily removed from the surface of the fiber. Semi-durable finishes are designed to have greater affinity for the fiber surface so they do not wash off easily. Finishes that maintain semi-durable hydrophilic characteristics typically contain components with a balanced hydrophilehydrophobe structure. As semi-durable hydrophilic performance increases, emulsion stability may decrease and make application to the substrate more difficult.

Hydrophobic Surface Modifiers

There are markets that require the nonwoven fabric to be hydrophobic. The challenge in these markets is to provide lubricity and antistatic protection required for processing without compromising the hydrophobicity of polypropylene inherent to the fiber surface.

While silicones are the most commonly used hydrophobic topical treatment, other options include fluorochemical and low viscosity specialty esters for end uses where silicone may not a viable option.

Antistatic Surface Modifiers

Whether hydrophilic or hydrophobic, many nonwovens products require static protection. Goulston Technologies, Inc. ha the expertise necessary to assist you with the proper antistat selection.

Comparison Table of Commercially Available Finish Systems

| Test | Lurol® PP-912 | Lurol® PP-6753 | Lurol® PP-9725 | Lurol® PP-10074 | Lurol® PP-L323 | Lurol® PP-L324 |

|---|---|---|---|---|---|---|

| Strike Through (Fifth Strike) | >300 sec | 2.75 sec | 4.78 sec | 85.17 sec | 6.12 sec | 2.8 sec |

| 24 hr. emulsion stability | Clear, Colorless, Stable | Milky, Opaque, Mild Creaming | Milky, Opaque, Stable | Light Yellow, Translucent, Stable | Milky, Opaque, Stable | Milky, Opaque, Stable |

| Antistat | Yes | No | No | Yes | Yes | No |

| Activity | 92% | 40% | 100% | 88% | 30% | 50% |

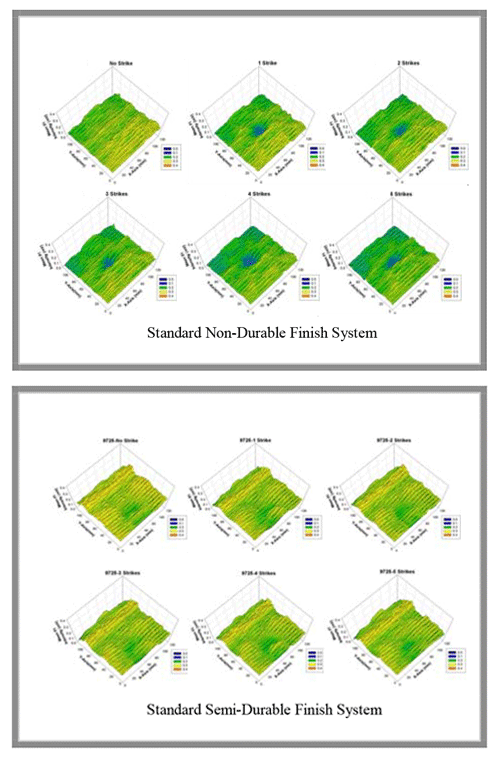

Multiple Strike-through Data

Reported in Seconds

| Sample ID | 1st Strike | 2nd Strike | 3rd Strike | 4th Strike | 5th Strike |

|---|---|---|---|---|---|

| Commercial Non-Durable Finish | 2.43 | 125.58 | >300 | >300 | >300 |

| Lurol PS-9725* Commercial Semi-Durable Finish | 2.45 | 2.79 | 3.15 | 3.35 | 4.78 |

Nonwoven PP samples applied at 0.5% on weight of fabric

*Antistat may be incorporated if necessary

Antimicrobial Treatment

Today’s consumer and commercial applications often require the incorporation of an antimicrobial treatment to the nonwoven fabric. Goulston Technologies, Inc. is proud to offer Lurol® AM-7 for use in conjunction with our topical systems. Benefits of this system include control of objectionable odors, unsightly stains and product deterioration. Ask you Account Representative for more information about this exciting enhancement for your nonwoven fabrics.

Multiple Strike-through Data

Reported in Seconds

| Sample | 1st | 2nd | 3rd | 4th | 5th | 6th | 7th | 8th |

|---|---|---|---|---|---|---|---|---|

| Lurol® PP-9725 | 2.58 | 3.23 | 3.28 | 3.13 | 2.96 | 3.08 | 3.40 | 3.86 |

| Lurol® PP-9725 w/AM-7 | 2.14 | 3.39 | 3.24 | 3.04 | 3.03 | 3.12 | 3.52 | 4.10 |

Nonwoven PP samples applied at 0.7% on weight of fabric + 0.1% Lurol® AM-7